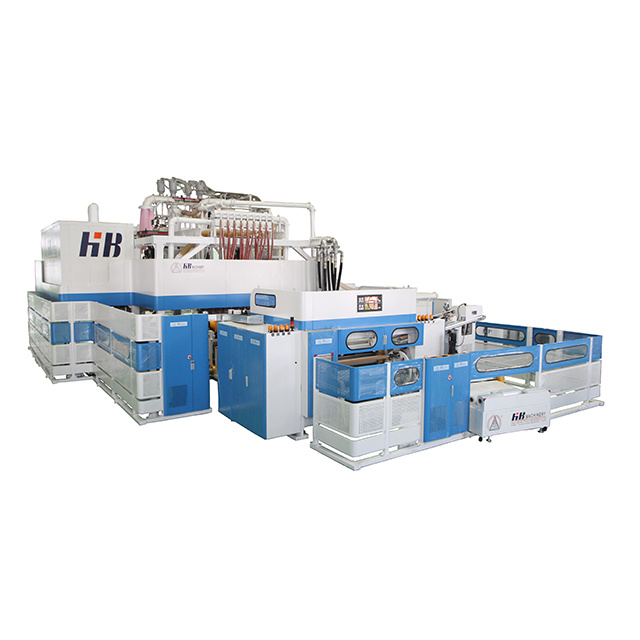

HB450/HB700 series four-axis cast PE stretch film/grass film production line (1500-6000mm)

- Commodity name: HB450/HB700 series four-axis cast PE stretch film/grass film production line (1500-6000mm)

- Product Details

-

HB450/HB700 series four-axis cast PE stretch film/grass film production line (1500-6000mm)This production line uses LLDPE (linear low-density polyethylene) as the main raw material, employing several different grades of resin, to produce self-adhesive single-sided or double-sided three-layer/five-layer to seven-layer stretch wrap film through an extruder. After using a special formula and process for grass film, it can also produce silage film for grass. Additionally, it can produce anti-rust stretch film for metal packaging, as well as anti-static stretch film for packaging materials that require high anti-static performance.This production line is also suitable for recycled materials, enabling the recycling of resources, effectively reducing carbon emissions, and aligning with international environmental protection trends and currents (output and speed depend on the quality and proportion of recycled materials used).Production line features1. This series of production lines uses imported fully automatic molds, equipped with thickness gauges, and employs energy-saving series motors in its electrical components, featuring low energy consumption, high automation, and labor-saving characteristics.2. The application of multi-layer co-extrusion technology allows for more flexibility and maturity in raw material usage according to different customer needs, resulting in lower formulation costs.3. The raw material feeding section can optionally use an automatic metering and mixing system, ensuring the rigor and accuracy of the formulation, reducing inaccuracies caused by human factors, saving labor costs, and improving product quality.4. An online longitudinal stretching device can be added according to customer requirements, enabling the production of ultra-thin pre-stretched wrap film online; it can also achieve edge folding and dual pre-stretching functions online.5. The winding section uses an excellent automatic film application device without adhesive tape. In the traditional method, tape is wrapped around the surface of the paper tube, relying on the tape's viscosity to adhere the stretch film to the roll. This can cause the film to stretch and deform during the roll change process, leading to poor base quality and affecting the surface quality of the film roll, resulting in some waste during use. Our automatic production line saves costs on tape, labor, time, and film waste.6. An automatic weighing device can be added, allowing the film roll to automatically weigh on a platform after winding, reducing the labor intensity of workers and improving production efficiency.7. The difference from traditional stretch film production lines is that the roll change uses a four-axis 90-degree roll change, which is fast, with no tail material, and a short overall action time for roll change. This means that during high-speed production, it can produce both 2KG hand rolls of stretch film and large rolls for machine use. This allows for the production and use of 3-inch and 2-inch paper tubes online, reducing the subsequent re-winding process, significantly lowering the investment in re-winding machine equipment and labor costs. Calculating based on 4 re-winding machines, this can save over 200,000 yuan in labor costs annually.8. The future development direction of large professional packaging film production enterprises will inevitably move towards high capacity, low energy consumption, and automated intelligence, phasing out low-capacity, high-energy consumption, and high-labor-intensity machinery. Therefore, this type of equipment is the model for future professional stretch film manufacturers.

Model specification SJLM-CR-Z 1500-4500mm

Screw diameter (mm) 65/135/90/65 80/115/115/65 65/125/65/125/65 80/135/80/135/80 90/90/150/150/90/90 90/90/150/150/90/90/90

Mold width (mm) 1900

2400

1900

2500

3500

5000

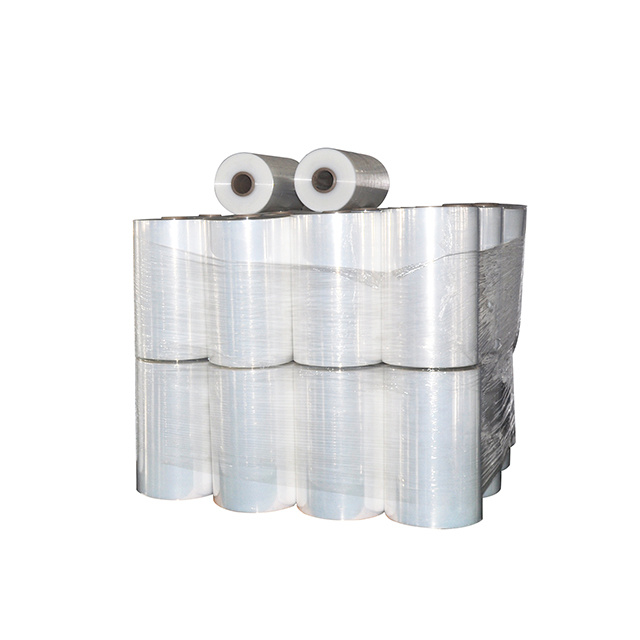

Finished product width (mm) 1500 (500×3 rolls) 2000 (500×4 rolls) 1500 (500×3 rolls) 2000 (500×4 rolls) 3000 (500×6 rolls) 4500 (500×9 rolls)

Finished product thickness (mm) 0.012-0.035

Film structure A/B/C/B/D

A/B/D/C/D/B/E

9/11/13/33/56 layers

Max extrusion capacity (kg/h) 850

1050

1200

1500

2200

2500

Mechanical design line speed (m/min) 450

700 700

550 Total power (kw) 600

850

800

1000

1250

1390

Dimensions (L×W×H) (m) 14×9×5.5

16×9.5×5.5

16×9×5.5

17×10×6

18×11×7

20×12×7.5

Weight (T) 45

55

55

60

70

75

online message