New Product Promotion

Classification:

News

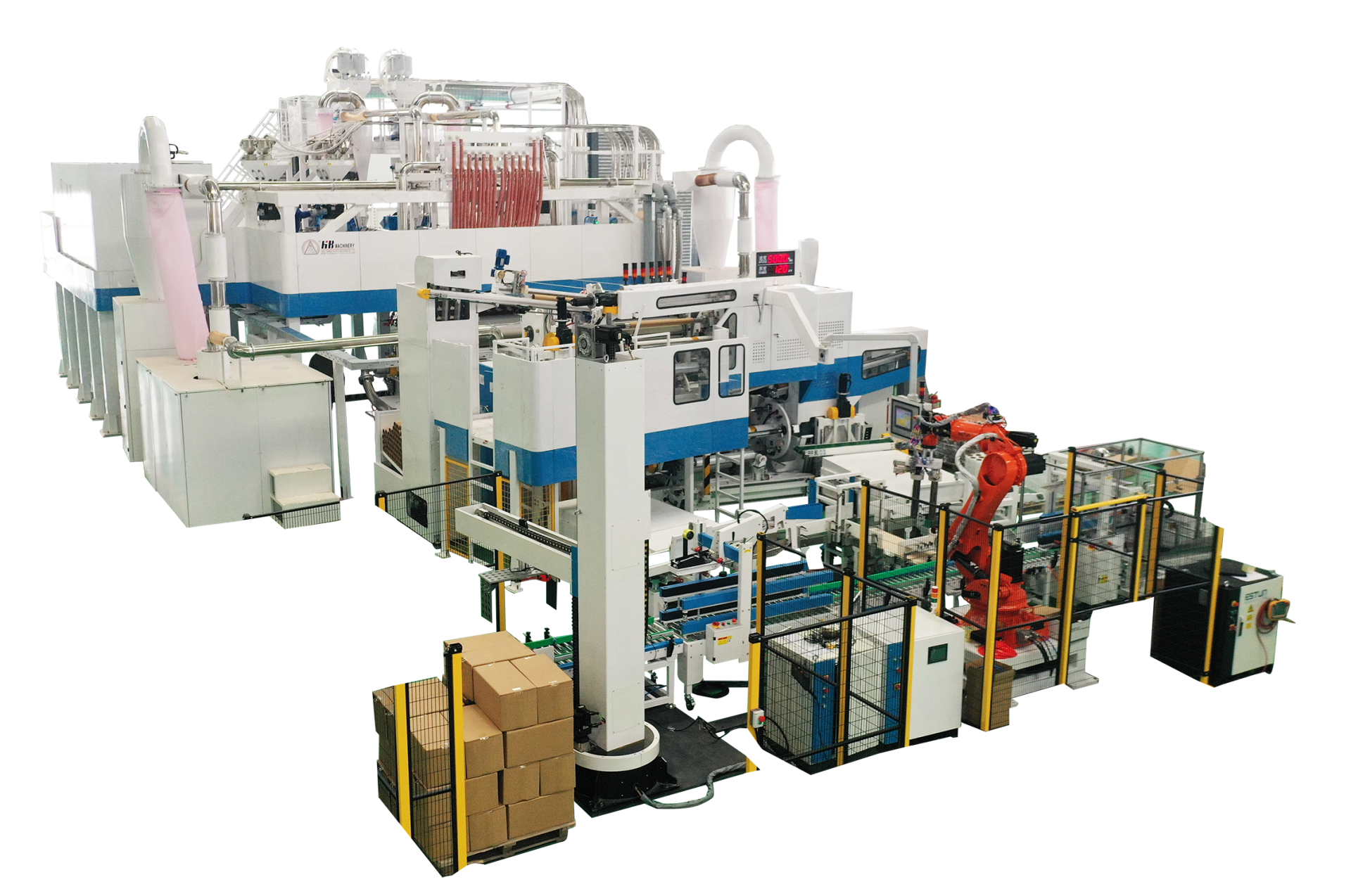

Xing Lehua Plastic Machinery Co., Ltd. is a subsidiary of Hebei Huabao Plastic Machinery Co., Ltd., established in 1998. The company focuses on technological innovation and is dedicated to the research, design, and production of various plastic machinery, specializing in the production of cast film machinery as a high-tech enterprise. Currently, our company has launched a new type of 56-layer nano winding film production line, fully biodegradable extrusion cast film production line, fluorine material cast film production line (PVDF/ETFE, etc.), wide CPP transparent film production line, and TPU car cover base film production line.

Create a national brand and share it with the world.

New Lehua Plastic Machinery Co., Ltd. is a subsidiary of Hebei Huabao Plastic Machinery Co., Ltd., established in 1998. The company focuses on technological innovation and is dedicated to the research, design, and production of various plastic machinery, specializing in the production of cast film machinery as a high-tech enterprise. Our company has recently launched a new 56-layer nano winding film production line, fully biodegradable extrusion cast film production line, fluorine material cast film production line (PVDF/ETFE, etc.), wide CPP transparent film production line, and TPU car cover base film production line.

01

CAST FILM LINE

New 56-layer nano winding film production line.

Nano winding film is formed through a 56-layer multi-layer co-extrusion technology at the nanoscale, combining various materials (PE, PP/POE, etc.) into a composite layered extrusion, resulting in a single-layer thickness at the nanoscale and a total of 56 layers of high-strength, high-toughness winding film.

Finished product width: 1500-4000mm.

Product thickness: 12-35um.

02

CAST FILM LINE

Fully biodegradable extrusion cast film production line.

This production line specializes in producing fully biodegradable films, using fully biodegradable materials such as polylactic acid (PLA) and PBAT, processed into films through the extrusion casting method, mainly suitable for packaging bags, household product packaging, daily necessities, food packaging, agricultural and industrial packaging, etc.; it can also be compounded with paper, non-woven fabric, cotton fabric, and other knitted fabrics for use in medical, sanitary, or other special fields.

Finished product width: 1000-2500mm.

Product thickness: 15-50um.

03

CAST FILM LINE

Fluorine material cast film production line (PVDF/ETFE, etc.).

This production line uses specially designed extruders and casting die heads to produce PVDF films through the extrusion casting method, applicable for solar cell backsheet films, water treatment permeable membranes, outdoor building protective films, and other special functional films. ETFE films can be used not only as building and agricultural films but also for automotive windscreen films, anti-pollution inner and outer packaging materials, battery separators, adhesive containers, conveyor belts in the food industry, solar receivers, flexible printed circuit boards, computer wires, and medical packaging films.

04

CAST FILM LINE

Wide CPP cast film production line.

This production line specializes in producing high transparency CPP flexible packaging films. The films produced by the casting process have special properties, such as small thickness tolerance, good transparency, good gloss, and good heat sealing properties. This film, after printing and bag making, is suitable for general composite films, aluminum-plated films, cooking films, and functional films, mainly used in the packaging industry for food, materials, and consumer goods.

Finished product width: 3500-6300mm.

Product thickness: 20-80um.

Production speed: 180-250m/min.

05

CAST FILM LINE

TPU car cover base film production line.

This production line mainly uses TPU aliphatic raw materials to produce transparent TPU car cover base films, and can also add different colored masterbatches to produce colored TPU car cover base films. Utilizing specially designed screws and casting forming technology, equipped with double-sided BOPET protective film automatic unwinding devices, online automatic thickness measurement, and fully automatic winding, advanced technologies are implemented to achieve automated stable operation of the production line, ensuring the production of TPU car cover base films. This base film undergoes subsequent gluing and surface treatment to produce high-quality car cover films.

Product width: 1400-1900mm.

Product thickness: 100-200um.

Be a responsible and accountable plastic machinery equipment manufacturer.

For over thirty years, Huabao people have adhered to the principle of quality.

We insist on systematic improvement, continuous optimization, and striving for excellence.

Let every product reflect our diligence and meticulousness.

Benchmark against advanced standards in the plastic machinery industry.

Engage in technological innovation, management innovation, and continuous surpassing.

Win market respect with quality and create a well-known brand in the industry.

Key words: